Our Extensive Capabilities

“Rainier Display is a hidden gem of a company.” “We have such a wide spectrum of capabilities, but not enough people know about us.” “We work with such a wide variety of machinery that we can accomplish almost any project.” These are some phrases that I have heard around the office as our company brainstorms how to get our name out there. From one-off prototypes to extensive branded environments, Rainier Display is equipped to handle any size project with precision and accuracy. Our 140,000 square foot facility in Seattle allows us the freedom to take on diverse projects while leveraging our wide variety of manufacturing capabilities. We have a long history of working with many different materials in our facility and designating full sections of our shop to be specialized in a specific media. This allows us to excel in a wide variety of capabilities.

What We Can Do

From rolled substrate printing, to lamination, to plotter cutting, we have everything that you could need for your next grand format printing job. Size is no obstacle at Rainier. We do large print jobs regularly; for example, we printed the flags that fly on the Space Needle!

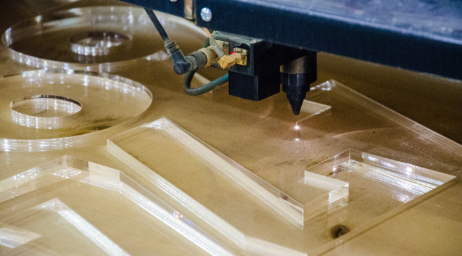

We can print from a roll or on a rigid material such as acrylic or wood. We can even print with haptic ink, making the print three dimensional to the touch! Our cutting technology is top of the line; we have laser cutting, laser engraving, CNC routing and even waterjet cutting, but that is not all. Our shop is also equipped with a fully functional wood shop, metal shop and sewing team.

What Makes Us Innovative

As you can see our capabilities are extensive. Here are examples of how we keep our machinery up to date for our customers to ensure accuracy and quality results.

In order to keep up with growing demand as well as reduce risk of down time on the cutting tables, we replaced two of our older Gerber cutting tables with state of the art Autometrix cutting tables. We added a 10’x 58’ as well as a 6’x58’ wide to improve our throughput and capabilities. These new tables run approximately double the speed of our past cutting tables. The wider table also improves our efficiency with manufacturing of larger panels with fewer seams. This is a prime example of how we strive for innovation and efficiency.

Our most impressive machine in the facility, and the biggest reason that we are labelled as an innovative company, is our 3D Freeform Tube Bender. After being approached to collaborate and produce a large art installation for the Salt Lake City Airport, we weren’t sure how we were going to physically manufacture the project, but we knew that we wanted to be a part of it! This led us to researching and travelling to a small Dutch town to find the tube bender in 2016. There are only a handful of tube benders in the world, and there is no limit to their capability. It can bend any commonly available metal including but not limited to; copper, brass, aluminum and steel. The bender even has a custom printer available for printing barcodes, saw lines, drill holes, alignment marks, etc. This machine is the epitome of precision and accuracy, and we are excited for the next project that someone dreams up for it.

Why Choose Rainier?

Our job is to bring your dreams and designs to life. With all of these capabilities in our shop, and all of our amazing employees, there is no limit to what we can accomplish for our clients. When choosing Rainier Display for your manufacturing needs, you are choosing a company that values putting customers first, being responsible, delivering results, having fun and being kind.

Check out our full list of capabilities on our website at https://oai-rainier.com/capabilities/